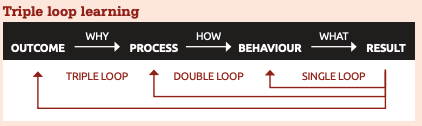

The triple loop learning model describes the importance of understanding your business goals (not to be confused with your purpose). The fundamental goal of any business is to return a profit on investment (focusing on profit rather than turnover was discussed in a previous article). Processes need to be aligned to this goal. Identifying processes that need improving can be done by asking a range of questions.

Where are the bottlenecks? What decisions cause the process to stall? Are you relying on an individual for a stage in the process when that individual has competing priorities? Can you take elements out of the process? For example, when is the clinical check done? Could this be done in bulk before the dispensing process starts, reducing the bottleneck of the pharmacist at the end of the process?

What is frustrating? Often frustrating things will be due to process problems and can be solved. Unfortunately, some processes seem like that gnat that needs to be circumcised; fiddly but required.

Where do problems occur? Poor process leads to problems and errors.

Is there a flow to work? Does work move smoothly or is it bitty and jerky? Creating an effective flow will improve efficiency, reduce problems and improve team satisfaction.

Are any tasks repeated in the process? A mantra of process mapping is to only touch a piece of paper once. Do you redo tasks in a process that takes time? Do you only need to do it once?

Are the things you use regularly to hand? Spending time fetching something regularly will make you inefficient. Some pharmacies have their most frequently dispensed products closer to the dispensary bench. If you do this, when did you check your top 50 lines? Has it changed?

Is space laid out to create a flow? Kitchen design uses a triangle between the sink, fridge and workspace as workflow operates around this space. How is your space used? Is it based upon old ways of working and hasn’t been updated?

Are regular tasks able to be automated? In some pharmacies I have seen purpose made stamps used as a template to ensure prescriptions are processed correctly. Drawing this template would take more time and introduces the opportunity for errors.

Do processes get in the way of each other? For example, the dispensing team can often be interrupted by patients wanting to know if their repeat prescription is ready. These interruptions reduce efficiency substantially. Could you have a team who will dispense without being interrupted and a front of house team who can answer these queries?

You might look at some of the issues you find and think that changing the process will only save you 15 seconds in the process, so why worry? You need to think of this in terms of scale. If you saved 15 seconds on 100 tasks a day, you will be given back 25 minutes a day. Scale this up by six days a week, 52 weeks a year, this equates to 130 hours, or at the national minimum wage, over £1,500. You may not be able to achieve that saving, but you could use the time to earn other income or improve job satisfaction for the team.

Pause to reflect

When was the last time you looked at the flow of dispensing in your pharmacy? Take a step back and watch the process. Which bits seem inefficient? Why are they inefficient? What could be done to make these steps more efficient? What will stop you making this change?